Wine Pump!

Recently, my partner Jess and I bought a home in Corrales, New Mexico. Corrales is a small agriculturally oriented community nestled west of the Rio Grande between Albuquerque and Rio Rancho (the two most populous cities in NM). The property we bought came with a small 0.4 acre vineyard, and it it took me about 18 months to get the vineyard back to producing some grapes. This year we had maybe 1/4 of the vineyard producing, but that was enough to generate 25 US gallons of wine! Earlier in the season, I was also able to make 3.5 US gal of white wine from the 4 Chardonnay vines.

I've bought a lot of wine-making equipment - fermentation vessels, tubing, grape crusher/destemmer, hydraulic wine press, wine analysis kits, wine transfer auto-siphons, etc. This hobby involves a lot of equipment and a lot of little "micro-steps," many of which involve transferring "must", grape juice, and wine (in various stages of completion) multiple times from one container to another while leaving settled-out yeast and other unwanted products behind. The process is called "racking" the wine. If you use a siphon system to move wine, it involves getting the "from" vessel to a position higher than the "going-to" vessel, which was fine for the 3.5 gal of Chardonnay, but try lifting 25 gallons of wine to a table to get it higher than the next container on the floor! Not so easy!

After the initial fermentation a winemaker always has to think about the wine's contact with oxygen. O² is the enemy of wine in storage! Sometimes, some wines can benefit from aeration or "breathing" just before drinking and just after opening a bottle, but continued availability of O² to wine in a bottle or being aged in a vessel usually has disastrous consequences. Big wineries have ways of managing this with wine transfers using special equipment and vacuum systems, etc. The hobbyist winemaker is encouraged to "think" about ways to limit O² incursion and exposure. Also, home winemakers have to do their best with what's readily available. Unfortunately, that means using PVC plastic hose attached to auto-siphons (also PVC). The hose distributed with these siphon kits is generally NOT food-grade hose... you open the box after Amazon delivers your new siphon and usually get a huge "whiff" of PVC plasticizers. There are some wine pumps that a small operation can buy, buy they are expensive, sometimes hard to use, hard to clean, and pump with impellers or by moving diaphragms - actions not gentle on the wine and which can inject or suck in unwanted air/oxygen exposure. Another home-use wine pump is well designed and even uses negative pressure to "de-gas" the wine, but require standard carboy opening sizes to fit the special bungs to make the system work, and it seems maybe a little slow and limited in transferring wine between vessels not right next to one another.

I put my mind to designing and building a pump that might address most of these issues, and that could be 3D printed and assembled with some inexpensive other items (like bearings and food-grade tubing) readily available online. I wanted it to be able to move wine volume at a good clip so open container time could be minimized for limiting O² exposure.

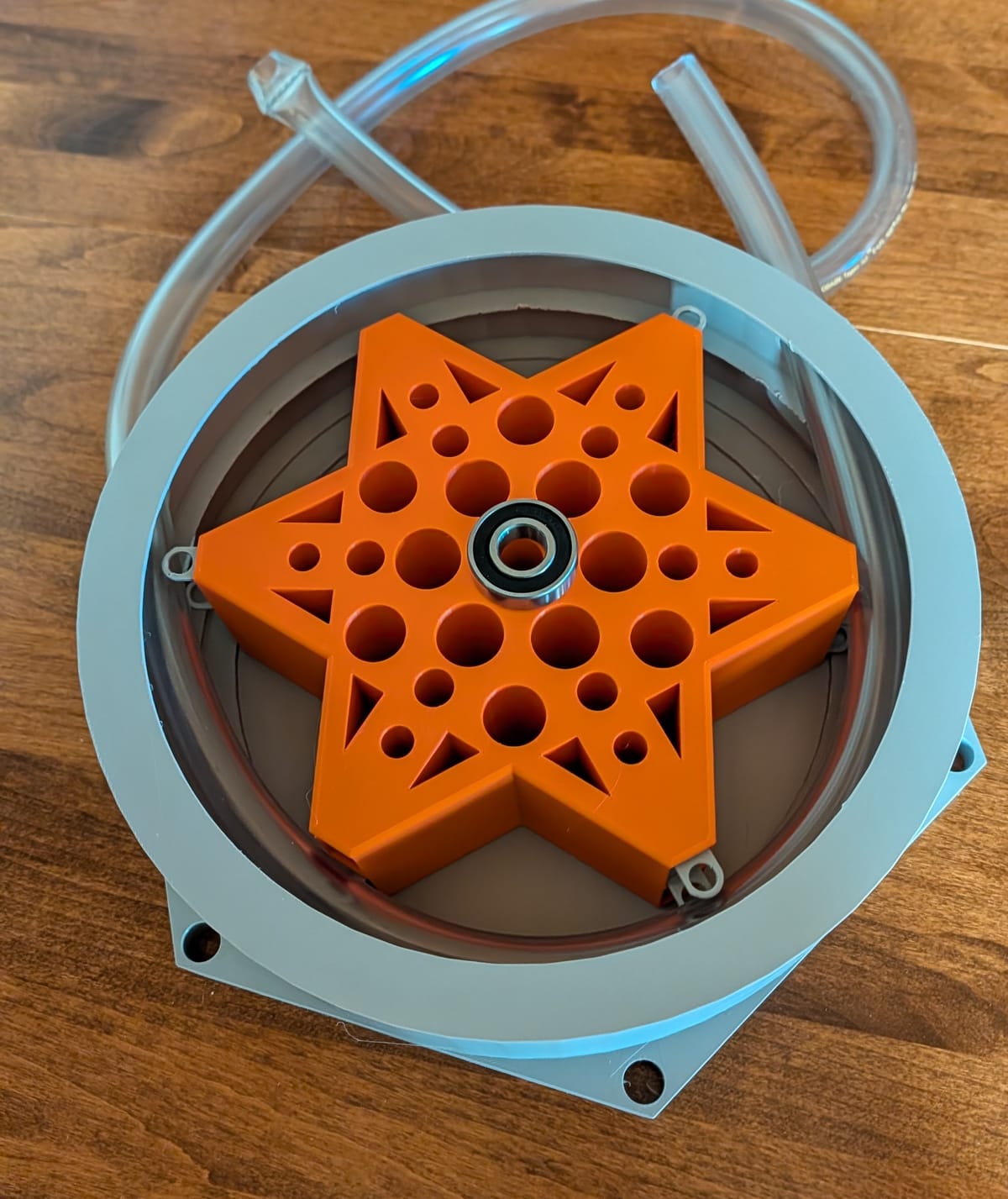

The picture above is my initial prototype peristaltic wine pump, 3D printed in PET. The tubing shown installed is a specialized "pump" (Tygon E-1000) tubing that was more expensive than I would like, but it has specs claiming it is for use in peristaltic pump applications and won't fail readily, and it doesn't convey any plasticizer smell or flavor to the conveyed liquids.

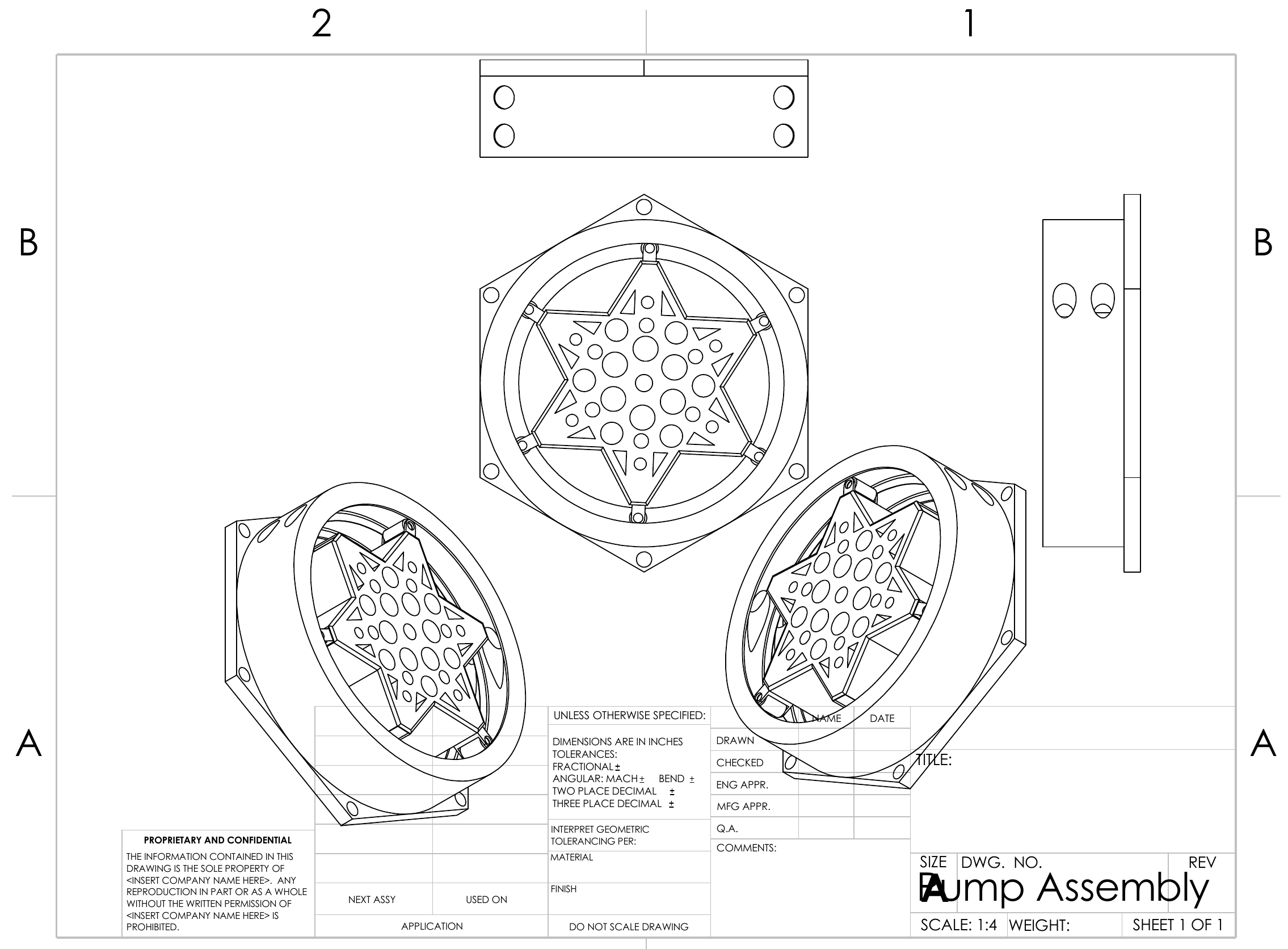

Here is an assembly drawing from my design work on the SolidWorks CAD program. I designed it so the rotor-impeller has 6 arms that can each be fitted with one or two bearing rollers that will compress the two tubing runs against the inside surface of the outer pump housing. I plan to take the two runs of pump tubing and have them "Y" into a single hose of slightly larger caliber (and much less expensive, but still food-grade) for the input and output runs to my wine vessels.

more to come...